Domestic independent development of six commercial vehicles + engine + aftertreatment assembly successfully rolled off the line

Release Date:2021-08-07 Number of views:862

On July 28, 2021, the National Key Research and Development Program project undertaken by the Research Center for Eco-Environment, Chinese Academy of Sciences and led by Academician He Hong's team: Air Pollution Causes and Control Technology Research Special Project (hereinafter referred to as "Air Special Project") -- "Diesel Vehicle Emission control Key Technologies and System Integration meeting National VI Standards" project results release and large-scale application roll-off ceremony was held in Dongfeng Commercial Vehicle Co., LTD. Shiyan Power Plant.

This year is the first year of the "14th Five-Year Plan". With the switch of national Six, the internal combustion engine and tail gas reprocessing industry has entered a critical period of high-quality development. The key technologies and system integration of diesel vehicle emission control that meet national six standards have become the focus, which is both a challenge and an opportunity for the upstream and downstream industries. Special project results released to the atmosphere and large-scale applications offline ceremony, the leaders and industry experts gathered, conspiracy to commercial vehicle diesel engine clean green and intelligent path of technological change, witness the first domestic "+ + engine for vehicle exhaust aftertreatment" comprehensive localization of independent development and industrialization of: Dongfeng commercial vehicle diesel engine co., LTD., a comprehensive control technology and industrialization of the vehicle and engine, ecological domestic SCR molecular sieve of r&d and industrialization of the Chinese Academy of Sciences, Anhui ActBlue key environmental protection co., LTD., exhaust after-treatment catalyst coating technology and industrialization project results release, such as listening to the project team members in the era of the six mission and core values.

Presentation by He Hong, Academician of the Chinese Academy of Engineering, on the Prospect of Air pollution Control under the Background of Carbon peaking and Carbon Neutrality

Dr. Yin Hang, deputy director of Vehicle Emission Monitoring Center of Chinese Research Academy of Environmental Sciences, delivered a keynote speech on Current status and future Direction of Heavy Vehicle emission Standards

Jiang Xuefeng, deputy chief engineer of Dongfeng Motor Group Co., LTD., interpreted "Dongfeng Commercial Vehicle Technology Strategy for Dual Carbon Target" and released the national project results of "Diesel Vehicle Emission Control Integration and Application Demonstration meeting National Six Standards"

Zhou Xianpeng, assistant general manager of Dongfeng Motor Group Co., LTD., spoke on behalf of the enterprise

Members of the atmospheric special project team, leaders and industry experts at the meeting

The participating experts and leaders visited the DDi75 (Longqing 300) engine of Dongfeng commercial vehicle Tianlong series equipped with autonomous control system, matching the SCR molecular sieve powder made by the Ecology Center of Chinese Academy of Sciences and Anhui ActBlue post-treatment assembly to put into production.

Mr. Liu Yi, chairman of Anhui ActBlue Environmental Protection Co., Ltd. introduced the independent research and development of post-treatment catalyst coating technology and mass production of packaging products to the experts and leaders.

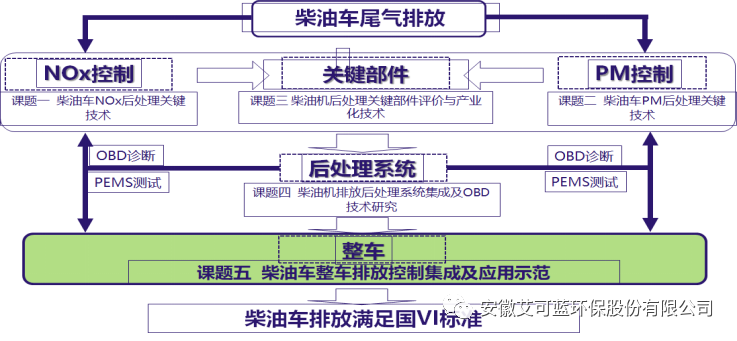

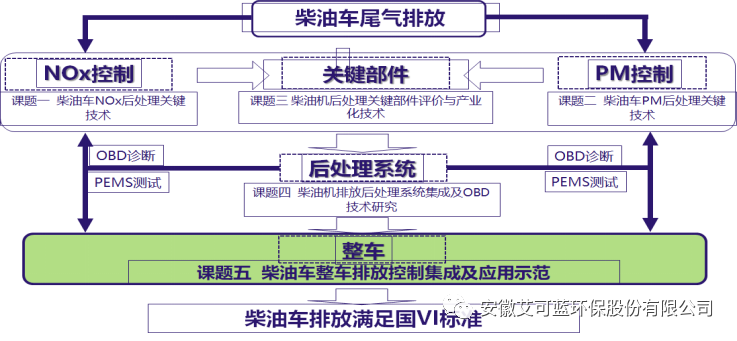

National Key R&D Program Project: Air Pollution Causes and Control Technology Research Special Project -- "Diesel Vehicle Emission Control Key Technologies and System Integration meeting National VI Standards" has been officially launched since July 2017, led by Ecology Center of Chinese Academy of Sciences, participating units: Tsinghua university, dongfeng commercial vehicle co., LTD., sinotruk group jinan power co., LTD, Anhui ActBlue environmental protection co., LTD., and other 10 units, aims to build a complete independent intellectual property rights of meet the six standard "key materials and technology - aftertreatment component production and evaluation of post-processing system matching integration and application of" complete technology industry chain, To form the largest production and supply system of diesel vehicle reprocessing system in China, overcome key bottlenecks, break foreign monopoly, and lead the industry development.

In order to advance the project smoothly and give a perfect answer to the country and society, the project team members unite as one and spare no effort to constantly conquer the core technology of each work plate. Even under the serious impact and impact of the COVID-19 epidemic, the project team members are unwavering and firm in their belief. Carry out all work in strict accordance with project objectives and organizational requirements, and organize regular exchanges of core issues and key technologies, discuss work direction and report work progress in the form of monthly work meetings, quarterly project meetings and special project meetings.

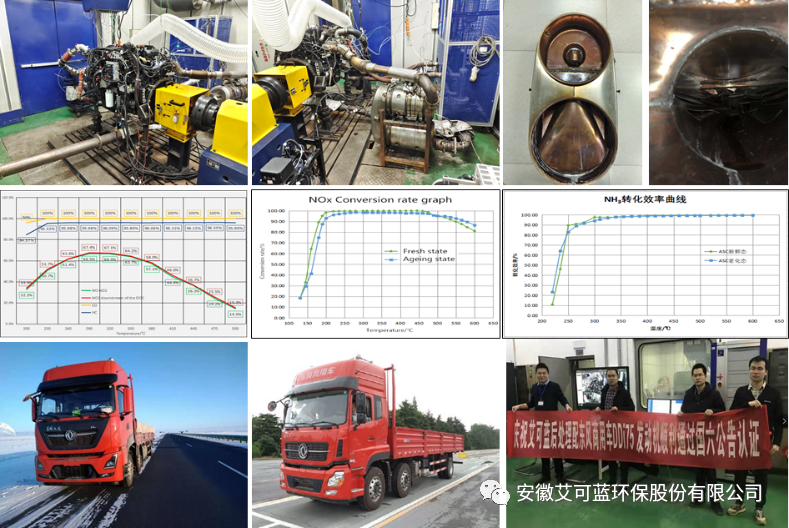

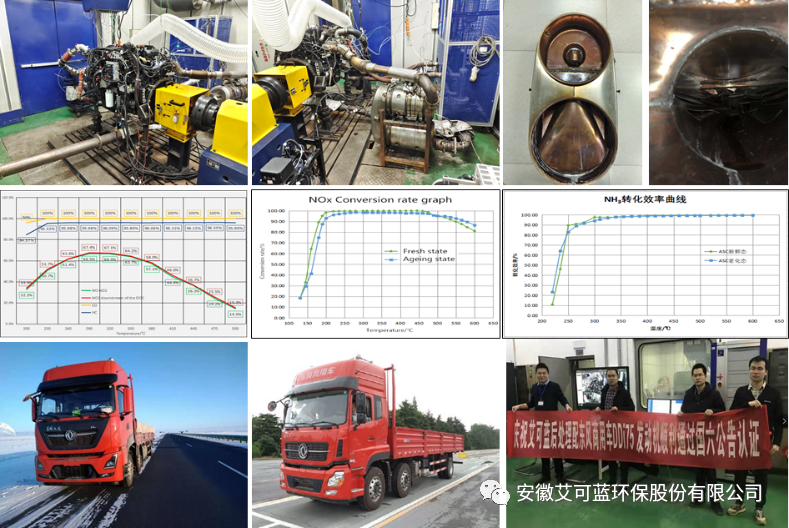

Anhui ActBlue environmental protection co., LTD., as the first domestic post-processing of the listed company social responsibility actively, close cooperation with project team members, not only based on the ecological independent research and development center of Chinese Academy of Sciences of molecular sieve powder technology to overcome the SCR system, the development of abroad six DOC and DPF system at the same time, and take the key work such as system integration and calibration tests. Taking Dongfeng commercial Vehicle project as an example, the total number of platform tests has reached 6,718 hours. In strict accordance with the technical development standards and requirements of Dongfeng commercial vehicle products, the company has successfully completed various technical verification and industrialization performance verification.

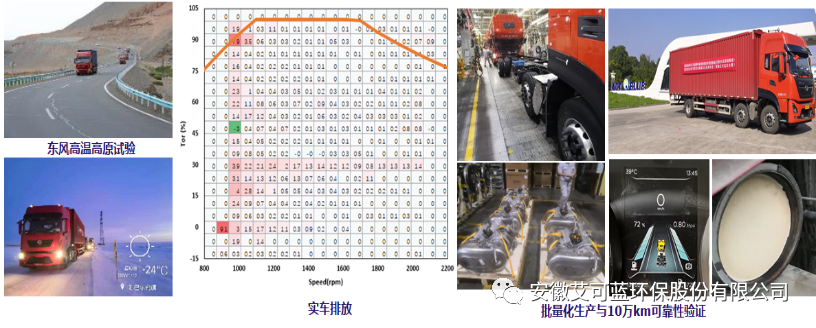

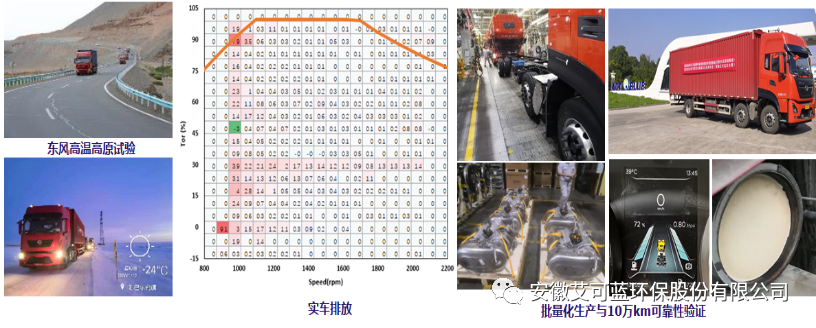

In the early process of packaging performance verification (back pressure, uniformity, crystallization, etc.) and monomer performance verification of catalyst (DOC, SCR efficiency, DPF capture capacity, etc.), ActBlue has overcome the core technology of high efficiency and crystallization resistance of the mixing device, and the key technology of rapid temperature rise of DOC and low temperature efficiency of SCR. Completed the development and selection of catalytic converters and started the post-processing calibration work successfully. Then in SCR performance calibration, DPF properties and regeneration and OBD calibration and verification, the state from fresh catalyst to catalyst aging state, from post-processing assembly validation to validation, the vehicle calibration test from the plains to the high temperature plateau alpine testing (both launch vehicle demonstration run for more than 2 years, after two rounds of three tenors validation, The total mileage is more than 2.4 million kilometers, the highest mileage of a single bike is more than 240,000 kilometers), in order to come up with the best products and ensure consistency, round after round of testing and verification, continuous optimization and iteration... In this process, ActBlue has solved the problems of sulfur resistance, assembly durability and reliability, product consistency and so on. The performance of the post-processing system has been continuously improved, and it has been highly recognized by customers. Compared with foreign counterparts, Acoran has a considerable performance and obvious cost-performance advantage.

At present, the problem of lack of core is making the industry feel the pain, and then the treatment system will be the next serious constraint on the high-speed and high-quality development of commercial vehicles. This with the support of national key r&d projects, led by the Chinese Academy of Sciences, key enterprises and famous university cooperation, successful research with independent intellectual property rights completely meet the VI standard "key materials and technology - aftertreatment component production and evaluation of post-processing system matching integration and application of" dragon technology system and form a complete industrial chain.

Thanks to all members of the project team for their responsibility! Thank Dongfeng Group this high specification of the offline ceremony, this is the ground a thunder: "Country six, we are ready!"

On July 28, 2021, the National Key Research and Development Program project undertaken by the Research Center for Eco-Environment, Chinese Academy of Sciences and led by Academician He Hong's team: Air Pollution Causes and Control Technology Research Special Project (hereinafter referred to as "Air Special Project") -- "Diesel Vehicle Emission control Key Technologies and System Integration meeting National VI Standards" project results release and large-scale application roll-off ceremony was held in Dongfeng Commercial Vehicle Co., LTD. Shiyan Power Plant.

This year is the first year of the "14th Five-Year Plan". With the switch of national Six, the internal combustion engine and tail gas reprocessing industry has entered a critical period of high-quality development. The key technologies and system integration of diesel vehicle emission control that meet national six standards have become the focus, which is both a challenge and an opportunity for the upstream and downstream industries. Special project results released to the atmosphere and large-scale applications offline ceremony, the leaders and industry experts gathered, conspiracy to commercial vehicle diesel engine clean green and intelligent path of technological change, witness the first domestic "+ + engine for vehicle exhaust aftertreatment" comprehensive localization of independent development and industrialization of: Dongfeng commercial vehicle diesel engine co., LTD., a comprehensive control technology and industrialization of the vehicle and engine, ecological domestic SCR molecular sieve of r&d and industrialization of the Chinese Academy of Sciences, Anhui ActBlue key environmental protection co., LTD., exhaust after-treatment catalyst coating technology and industrialization project results release, such as listening to the project team members in the era of the six mission and core values.

Presentation by He Hong, Academician of the Chinese Academy of Engineering, on the Prospect of Air pollution Control under the Background of Carbon peaking and Carbon Neutrality

Dr. Yin Hang, deputy director of Vehicle Emission Monitoring Center of Chinese Research Academy of Environmental Sciences, delivered a keynote speech on Current status and future Direction of Heavy Vehicle emission Standards

Jiang Xuefeng, deputy chief engineer of Dongfeng Motor Group Co., LTD., interpreted "Dongfeng Commercial Vehicle Technology Strategy for Dual Carbon Target" and released the national project results of "Diesel Vehicle Emission Control Integration and Application Demonstration meeting National Six Standards"

Zhou Xianpeng, assistant general manager of Dongfeng Motor Group Co., LTD., spoke on behalf of the enterprise

Members of the atmospheric special project team, leaders and industry experts at the meeting

The participating experts and leaders visited the DDi75 (Longqing 300) engine of Dongfeng commercial vehicle Tianlong series equipped with autonomous control system, matching the SCR molecular sieve powder made by the Ecology Center of Chinese Academy of Sciences and Anhui ActBlue post-treatment assembly to put into production.

Mr. Liu Yi, chairman of Anhui ActBlue Environmental Protection Co., Ltd. introduced the independent research and development of post-treatment catalyst coating technology and mass production of packaging products to the experts and leaders.

National Key R&D Program Project: Air Pollution Causes and Control Technology Research Special Project -- "Diesel Vehicle Emission Control Key Technologies and System Integration meeting National VI Standards" has been officially launched since July 2017, led by Ecology Center of Chinese Academy of Sciences, participating units: Tsinghua university, dongfeng commercial vehicle co., LTD., sinotruk group jinan power co., LTD, Anhui ActBlue environmental protection co., LTD., and other 10 units, aims to build a complete independent intellectual property rights of meet the six standard "key materials and technology - aftertreatment component production and evaluation of post-processing system matching integration and application of" complete technology industry chain, To form the largest production and supply system of diesel vehicle reprocessing system in China, overcome key bottlenecks, break foreign monopoly, and lead the industry development.

In order to advance the project smoothly and give a perfect answer to the country and society, the project team members unite as one and spare no effort to constantly conquer the core technology of each work plate. Even under the serious impact and impact of the COVID-19 epidemic, the project team members are unwavering and firm in their belief. Carry out all work in strict accordance with project objectives and organizational requirements, and organize regular exchanges of core issues and key technologies, discuss work direction and report work progress in the form of monthly work meetings, quarterly project meetings and special project meetings.

Anhui ActBlue environmental protection co., LTD., as the first domestic post-processing of the listed company social responsibility actively, close cooperation with project team members, not only based on the ecological independent research and development center of Chinese Academy of Sciences of molecular sieve powder technology to overcome the SCR system, the development of abroad six DOC and DPF system at the same time, and take the key work such as system integration and calibration tests. Taking Dongfeng commercial Vehicle project as an example, the total number of platform tests has reached 6,718 hours. In strict accordance with the technical development standards and requirements of Dongfeng commercial vehicle products, the company has successfully completed various technical verification and industrialization performance verification.

In the early process of packaging performance verification (back pressure, uniformity, crystallization, etc.) and monomer performance verification of catalyst (DOC, SCR efficiency, DPF capture capacity, etc.), ActBlue has overcome the core technology of high efficiency and crystallization resistance of the mixing device, and the key technology of rapid temperature rise of DOC and low temperature efficiency of SCR. Completed the development and selection of catalytic converters and started the post-processing calibration work successfully. Then in SCR performance calibration, DPF properties and regeneration and OBD calibration and verification, the state from fresh catalyst to catalyst aging state, from post-processing assembly validation to validation, the vehicle calibration test from the plains to the high temperature plateau alpine testing (both launch vehicle demonstration run for more than 2 years, after two rounds of three tenors validation, The total mileage is more than 2.4 million kilometers, the highest mileage of a single bike is more than 240,000 kilometers), in order to come up with the best products and ensure consistency, round after round of testing and verification, continuous optimization and iteration... In this process, ActBlue has solved the problems of sulfur resistance, assembly durability and reliability, product consistency and so on. The performance of the post-processing system has been continuously improved, and it has been highly recognized by customers. Compared with foreign counterparts, Acoran has a considerable performance and obvious cost-performance advantage.

At present, the problem of lack of core is making the industry feel the pain, and then the treatment system will be the next serious constraint on the high-speed and high-quality development of commercial vehicles. This with the support of national key r&d projects, led by the Chinese Academy of Sciences, key enterprises and famous university cooperation, successful research with independent intellectual property rights completely meet the VI standard "key materials and technology - aftertreatment component production and evaluation of post-processing system matching integration and application of" dragon technology system and form a complete industrial chain.

Thanks to all members of the project team for their responsibility! Thank Dongfeng Group this high specification of the offline ceremony, this is the ground a thunder: "Country six, we are ready!"

- Previous post:There is no

- Next post:There is no